What does it mean to achieve excellence in business? The idea has been around for decades and some might attribute it to Dr. Joseph Juran who taught Japanese business leaders how to improve quality to expand their growth and revenue around the globe..

According to the concept of operational excellence, continuous improvement allows organizations to reach higher levels of service and product delivery through better processes and standards. This ultimately leads to competitive advantage and the acquisition of greater market share in any given industry.

Getting to better business performance is easier said than done, though. While the ultimate goal is clear and straightforward, achieving operational excellence can be highly complex – especially at the enterprise level.

It’s not something that happens overnight, either. Improvement on many levels, however, can be realized by any organization, and it’s the key to unlocking a company’s full potential.

One must realize that operational excellence is a broad term that is interpreted in various ways, thus requiring a thorough explanation.

That said, let’s dive deeper into the concept of operational excellence, its core principles, and ways to achieve it.

What Is Operational Excellence?

Operational excellence is not a straightforward concept to define. There are several different interpretations of the term, with three primary approaches sharing the spotlight.

The broadest definition is that operational excellence is executing a business strategy more effectively and consistently than competitors. This, in turn, should result in increased revenue, lower operational risk, and lower operating costs.

But where would one start with such a vague categorization? There is a lot to unpack in such a broad view. For now, it’s a good foundational perspective.

Another popular definition describes operational excellence as something that occurs when all employees can see the flow of value to the customer and fix it before it breaks down.

In this definition, we see that the focus is on any component of business execution that pertains to creating more and better value for the customer. Excellence can only be achieved when the entire organization is well-orchestrated and organized around a “customer-first” philosophy.

The idea behind it is that employees focus on maintaining the detailed execution of the flow while management focuses on how customer value creation plays a critical strategic role in growing and expanding the business.

Lastly, many define operational excellence as a philosophy. This approach embraces problem-solving, teamwork, and leadership as the key to continuous improvement.

In other words, it’s not a set of activities but rather a mindset coinciding with the company culture. The culture where a business strategy focuses on customers’ needs, their experience, employee productivity and empowerment, and improving current activities within all levels of an organization.

So what, then, is operational excellence? Is it a set of activities or a mindset?

We strongly believe that it’s both.

Achieving operational excellence involves changes to a company’s culture and the principles by which the organization operates. It’s these strategic transformations that enable changes to the external and internal processes needed to improve the business’s operations.

Operational Excellence and Continuous Improvement

We’ve mentioned that operational excellence is key to continuous improvement. Indeed, these two terms are often seen together. You may even encounter content that uses the two ideas interchangeably.

However, while strongly connected, operational excellence and continuous improvement have distinctions that separate them. .

Continuous improvement is an ongoing effort to improve business processes, services, products, customer experience, etc. It happens incrementally over time, improving operational processes systematically rather than instantly through some major breakthrough.

However, while incremental improvements are vital for an organization to advance and create business transformation, they are not enough.

As the company continues to evolve and improve its processes, it needs a way to make greater strides beyond incremental improvements. And that’s where operational excellence steps in, changing the organizational culture to help create sustainable breakthrough improvement throughout the company.

In the end, that’s what operational excellence is all about.

Sure, it helps increase employee productivity, cut costs, and boost revenue. However, it does that through creating a sustainable culture within the organization as well, unlocking its full potential.

The idea here is to apply the right tools and processes to create a work culture that performs day in and day out. A work culture that empowers and motivates each employee to take responsibility for the flow of the operation.

These kinds of changes allow for implementing key improvements, producing valuable products, and providing high-quality services, resulting in long-term sustainable growth.

10 Core Principles of Operational Excellence

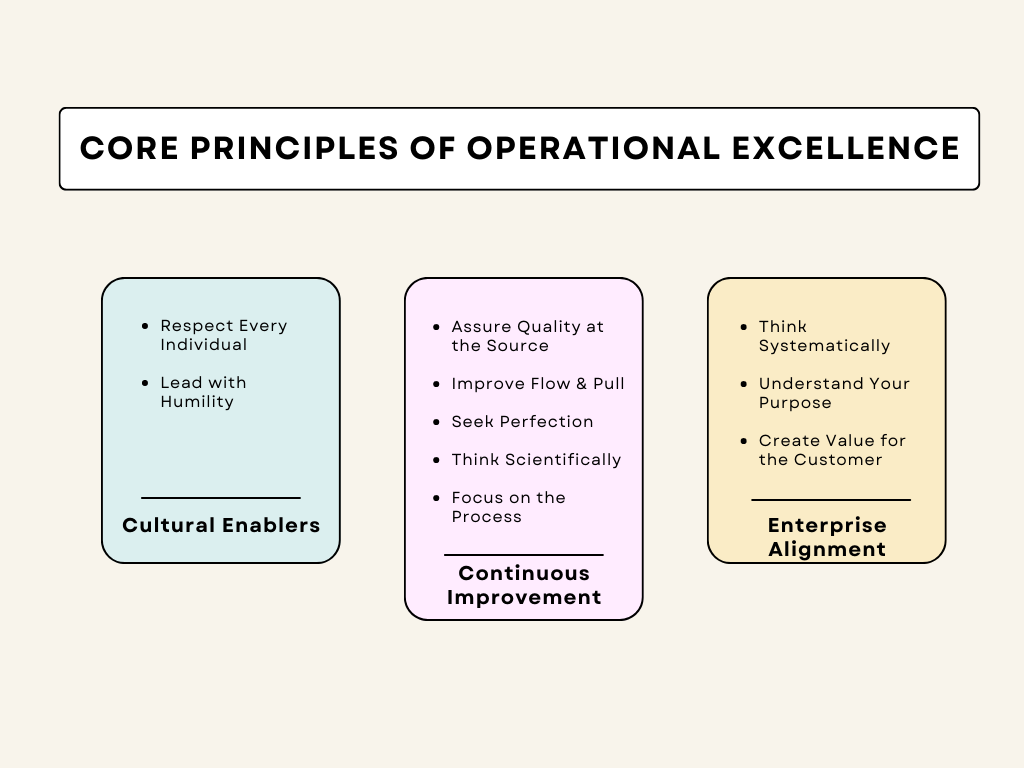

When operational excellence includes consideration of culture as well as execution of work, there are several guiding principles of the Shingo Model that are valuable to know. This model is the basis for building a sustainable work culture within the company, enabling it to achieve operational excellence in ways that others models can’t deliver.

The Shingo Model distinguishes ten guiding principles divided into three categories:

- cultural enablers,

- continuous improvement,

- and enterprise alignment.

#1 Respect Every Individual

According to Shingo, every individual deserves respect. It encourages organizations to empower and motivate their employees to contribute to the changes within the company.

That, however, requires showing them the respect they deserve.

The best way to demonstrate respect is to involve employees in making the necessary improvements to their teams and departments.

Asking them for their input is an excellent way to show respect. They will feel more empowered, believing their work and ideas can contribute to changes in the organization’s processes.

#2 Practice Humility

Organizational leadership requires humility.

While some consider it a weakness, acknowledging your shortcomings and looking for a better solution elsewhere is the fastest way toward improvements.

Suppose you’re willing to listen to other people’s ideas. In that case, you’ll gain their respect and empower them to continuously improve and come up with possible solutions you can use to achieve excellence.

#3 Strive Toward Perfection

Many believe that achieving perfection is impossible. After all, there will always be something that could work more efficiently. It doesn’t mean you shouldn’t seek perfection, though.

Setting a bar high will create a different mindset in your organization. By stating certain principles and long-term solutions, your employees will be more willing to follow your lead and improve the quality of their work.

#4 Think Scientifically

Continuous improvement and operational excellence both rely on constant experimentation. Scientific thinking breeds innovation and encourages creativity and exploring new ideas without fear of failure.

It also involves the process of continuous learning and evalution of which processes work and which don’t. Sometimes, companies need to make radical changes to how they approach execution. How will you know whether it’s necessary or optimized if you don’t try various approaches?

With experimentation comes the need for data collection and reporting. So, be prepared to go deeper in this area if you don’t already have sufficient means for doing so.

#5 Focus on the Process

It’s easy to blame other people when something goes wrong. And sure, people do make mistakes. In many cases, however, the problem is rooted in bad processes, not the person.

Think about it. Even the best employee can’t consistently produce exceptional results if the process is problematic.

That said, instead of pointing fingers, focus on repairing broken processes. Assess what might be wrong with them and which parts require improvements. Then, make the necessary adjustments and achieve desired outcomes.

#6 Assure Quality at the Source

This principle derives from the previous one. It states that you can only assure the quality of the process if every part is done correctly.

Organize work and visualize flow so that every potential problem immediately becomes visible. Then, when a mistake occurs, employees can eliminate and correct it before continuing.

#7 Improve Flow and Pull

The ultimate goal of every organization is to deliver maximum value to the customer. That requires every process to be as perfect as possible. Interruptions create waste, disrupting the flow and severely impacting the company’s efficiency.

The insight behind this principle is to analyze customer demand and ensure your business is meeting it. Creating more or less can cause disruptions and adversely affect customer experience and workflow.

#8 Think Systematically

Your organization is a system of many interconnected parts. And to ensure they work correctly, you need to understand their relationship.

It’s the core of process management and a vital part of running a business, as it allows you to make the right calls and improvements.

Avoid narrow vision and enable clear and open communication. Think systematically and use visual workflow software to monitor the flow between the processes.

#9 Understand Your Purpose

If your employees don’t understand your goals and mission statement, how are they supposed to work toward achieving them?

Everyone, from management to front-line employees, must understand the direction of your changes. They need to know why the organization exists, its core objectives, and how it wants to achieve them.

Emphasize your vision daily, and your employees will align their actions and goals with the company’s objectives.

#10 Create Value for the Customer

All these changes should lead to creating value for the customer. For this, however, your organization needs to understand its customer needs first.

That doesn’t end there, though.

Through continuous improvement, the business should always work to learn more about its customer’s needs and expectations. They tend to shift, and if an organization stops delivering value to the customer, it stands no chance in a competitive market environment.

Operational Excellence Methodologies

Achieving operational excellence is possible through numerous methodologies. There’s no one-size-fits-all here. Which methodology you choose will depend on your individual needs, goals, the size of the organization, its structure, etc.

First, though, you need to learn your options. The most popular methodologies include:

- Lean manufacturing,

- Kaizen,

- Six Sigma,

- Kanban,

- and 5-S System.

We’ll discuss them in more detail in the following paragraphs.

Lean Manufacturing

Lean manufacturing is a systematic method focused on eliminating waste in a production system. It’s based on the principle that everything you do in business should focus on adding value to the customer.

This approach states that an organization needs to focus on improving its products and services to stay competitive. That can only be achieved if all processes provide added value. If a process or its part fails to do that, it should be eliminated.

Kaizen

Kaizen is the Japanese term that translates to “change for the better.” In business, it’s nothing else than our old friend, continuous improvement.

Kaizen emphasizes teamwork, stating that positive business transformation can only occur if teams work together proactively, taking responsibility for their areas. Only by working together can the organization grow.

It teaches that even small changes, when applied continuously, can become a driving force over time and produce excellent results.

Six Sigma

Six Sigma can be defined as a set of tools, techniques, and methodologies which aim to improve business processes. The final result should be an improved product or service.

The goal is to identify and eliminate variation, resulting in improved customer experience and added value.

Implementing Six Sigma is based on five principles:

- focusing on the customer,

- identifying the problem,

- getting rid of waste,

- putting the process in motion,

- and creating a culture of change and flexibility.

Kanban

Kanban works best in manufacturing. It’s a visualization technique that involves displaying production and inventory information in visible areas to signal over and under production, lack of inventory, production disruptions, etc.

Its goal is to produce only according to customer demand, eliminating waste, decreasing overproduction, and reducing inventory in the process.

5-S System

This organizational method derives from five Japanese words – seiri, seiton, siesu, seiketsu, and shitsuke. They translate to organize, tidiness, cleanliness, standardize, and sustain.

It involves transforming the workspace, making it safer, cleaner, and organized to improve the quality of work and productivity. A result is a safer and better workplace where employees want to spend their time.

How to Achieve Operational Excellence?

We know it’s a lot to process, but understanding the principles on which operational excellence is built is crucial if you want to implement it in your organization.

And now that we have the theory out of the way, we can get to the more practical part of this guide and explain how you can achieve operational excellence.

Follow our tips and take your organization to a whole new level.

Develop and Communicate Your Vision

First things first, you need a plan. To prepare one, you need to do your research on which processes work in your company and which require improvements.

Check the morale in each team and measure productivity. Also, be sure to measure your customers’ satisfaction to see whether your products or services lack value.

Once you get all the necessary information, set up a framework you want your business to follow and come up with a clear vision of how you wish to achieve your objectives. Once you have it written down, communicate it to your employees and make sure they understand it.

Getting everyone on board is the most significant step toward achieving operational excellence. When getting started, try not to overthink it. The key to any kind of process improvement is to just get started.

Use the Right Tools

Operational excellence requires measurement and reporting. It also demands attention to detail and a scrutinized approach toward each process within the organization.

At the same time, you’ll need to manage current workflows to ensure there aren’t any disruptions while you implement changes.

That said, using the right workflow management tool is a must. HighGear can help you with that.

Using our state-of-the-art, no-code workflow application platform, you’ll be able to automate workflows, assign tasks, and review reports to help ensure your organization continues to operate at the highest level.

Emphasize Teamwork

As mentioned several times throughout this guide, operational excellence is based on teamwork. Empowering your employees will keep them motivated and productive, enabling them to react whenever they notice abnormal flow in the process.

Change the organizational culture and involve your employees in that process. The best collaborations occur where everyone feels seen and heard.

Show your team the respect it deserves, and they will repay you with fresh ideas, loyalty, and productivity beyond imagination.

Embrace Failure

Some say that there’s no place for failure in business. And sure, when finances are involved, even the tiniest mistake can be disastrous. However, when talking about operational excellence, embracing failure is the cornerstone.

First, it allows you to see which improvements work for your business. If you make a mistake, you can learn from it and correct it in future occurrences.

Secondly, it encourages your employees to think outside the box and develop new and fresh ideas. It creates an atmosphere of respect, boosting motivation and productivity throughout the company.

Create Repeatable Processes

Repeatable processes are key to achieving operational excellence. They make it easier to duplicate success and streamline workflows, ensuring your organization works like a well-oiled machine.

The best way to drive significant improvement is to automate your workflow. It will allow you to design custom processes to meet your business requirements and maintain productivity throughout your workforce.

Key Takeaways

Although it’s impossible to create a perfect business, achieving operational excellence is as close as one can get toward that goal.

And now that you know how everything about it, it’s time for you to implement the necessary changes and start a new chapter in your entrepreneurial career. Using our tips and HighGear’s workflow management tool, you’ll be able to take your organization to a whole new level.

But remember, it’s not just about the action. It’s about the mindset.

Completing operational excellence within your organization can happen only if you rethink how you do business. You may even be forced to turn your current company culture upside down.

If you’re ready to take that step, nothing will stand in your way toward operational excellence. Reach out to HighGear to learn more.