Empower Efficiency

Optimize Operations

Navigate supply chains, scale production, and streamline delivery – all without writing a single line of code.

Trusted by leading manufacturing companies worldwide

Costly Consequences: Are Spreadsheets and Old Apps Slowing You Down?

Identifying Operational Roadblocks

- ERP Limitations: Are you finding ERP systems prohibitively expensive or frustrating due to gaps in process coverage?

- Tracking Challenges: How often do you struggle to keep up with changing customer demands due to outdated tools?

- Inventory Management: Is poor inventory control leading to excess stock or critical shortages?

- Delayed Insights: Are delayed reports affecting timely decision-making and operational agility?

- Audit Concerns: Have recent audits revealed significant red flags or compliance issues that could risk your operations?

Quantifying the Business Impact

- Lost Opportunities: Inefficiencies cause missed critical business opportunities, impacting your bottom line.

- Reputational Damage: Regulatory breaches can irreparably damage a company’s public image.

- Revenue and Capacity Barriers: Impaired operational capability hinders efforts to expand revenue streams.

- Decision-Making Delays: Inefficient processes lead to inferior decision-making and costly delays.

- Organizational Friction: Outdated technology causes friction and impedes smooth operational flow.

Customer Testimonials

We had interdependent processes without a system to connect them. With HighGear, we can manage those legacy, homegrown solutions that we’re comfortable with, and automate it in a much, much nicer way.

Prior to having HighGear, we could not report the value of the workload that we were doing in engineering. Once we implemented HighGear and we started showing the report capabilities, the dashboards, people started understanding.

HighGear is very good at giving everybody the information they need in the way they need it. There’s all the foundational aspects of HighGear, which are all great, but ultimately the ability to communicate that to all the people on the team is what’s really impactful.

How is HighGear Different?

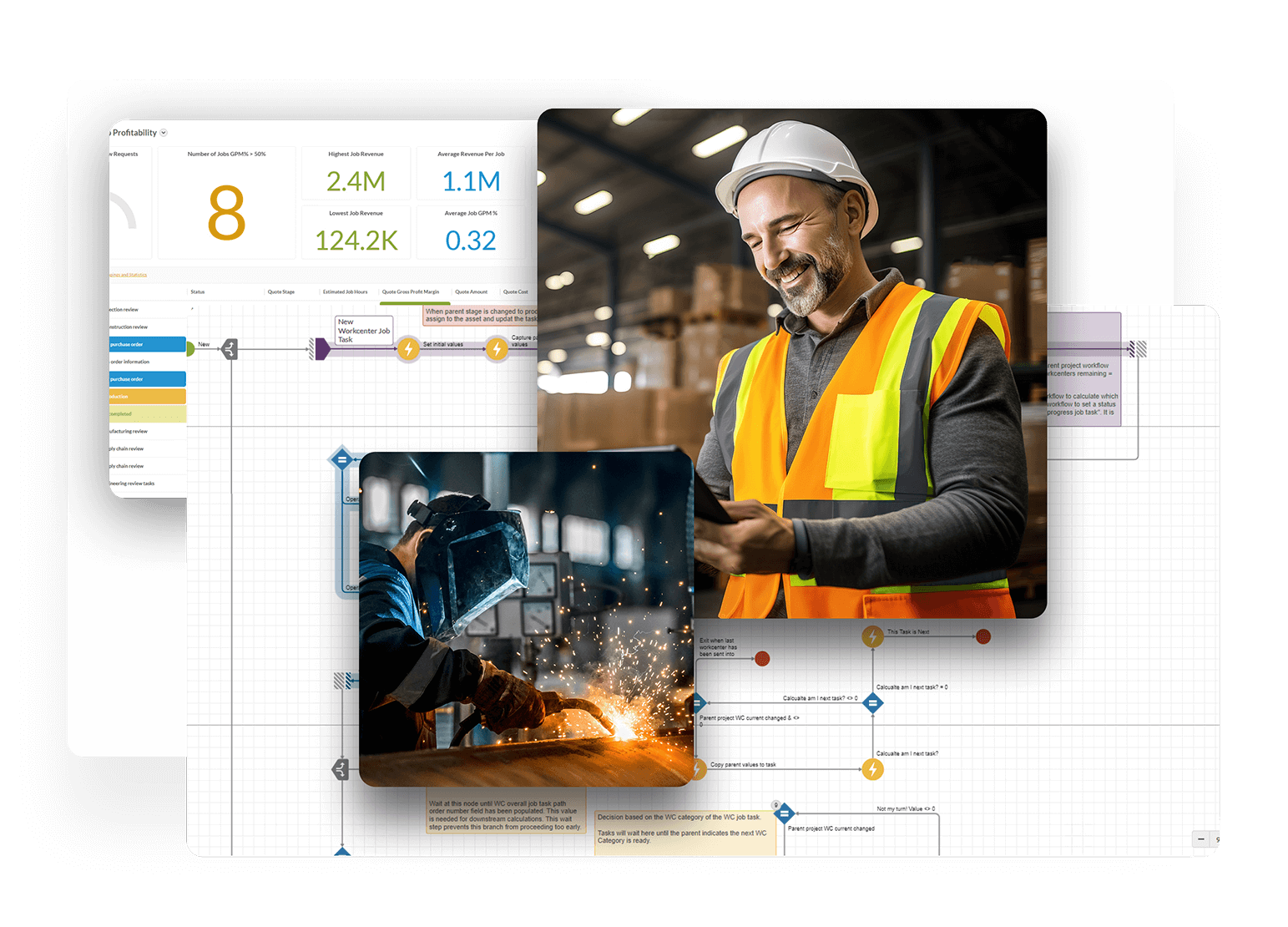

Efficiency and flexibility have never been more crucial, but traditional workflows struggle to keep up. From the back office to the factory floor, HighGear’s no-code workflow management system helps you streamline operations, boost efficiency, track the data you need, and never miss a reporting deadline.

Put Workflow to Work for You

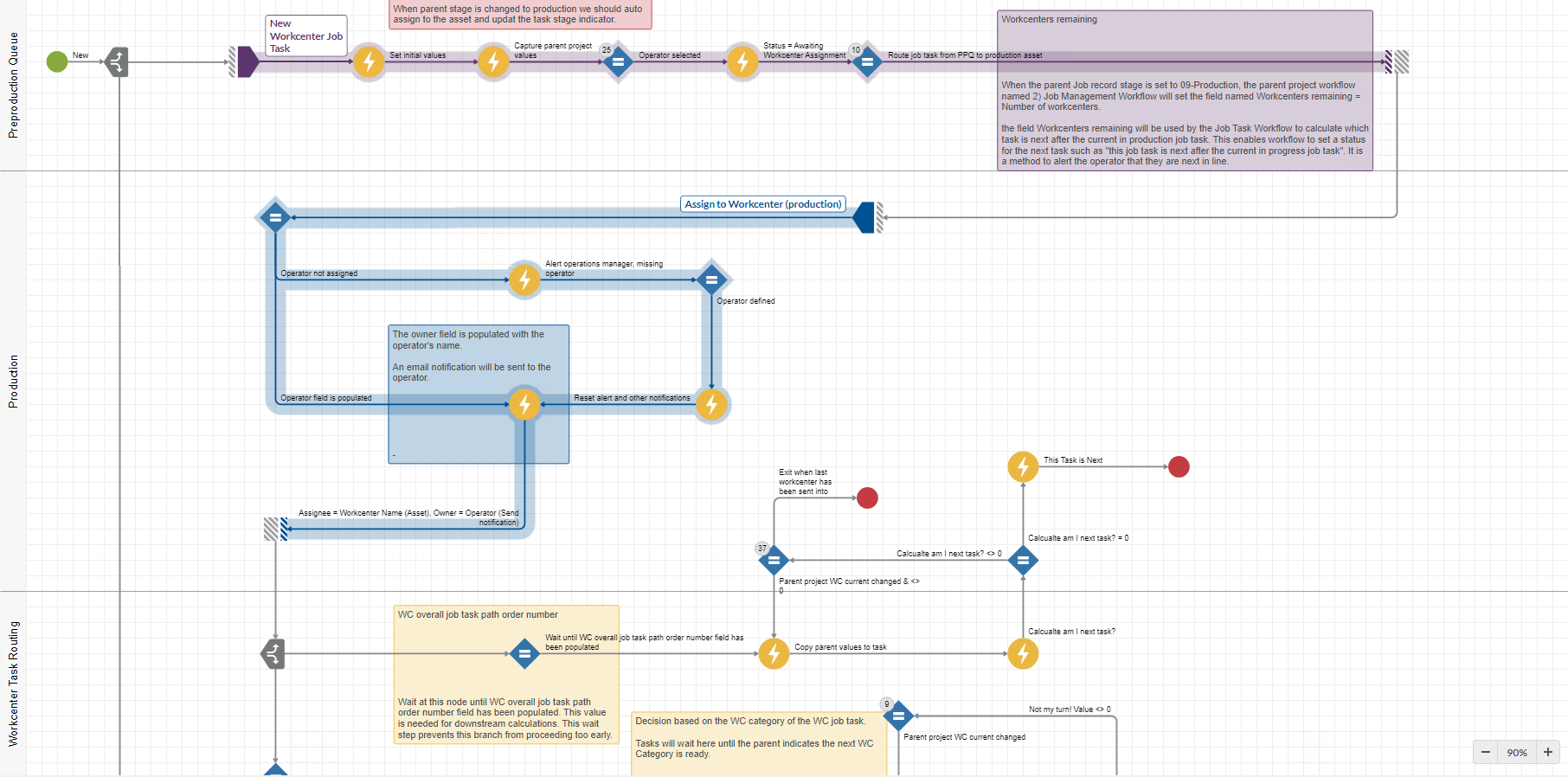

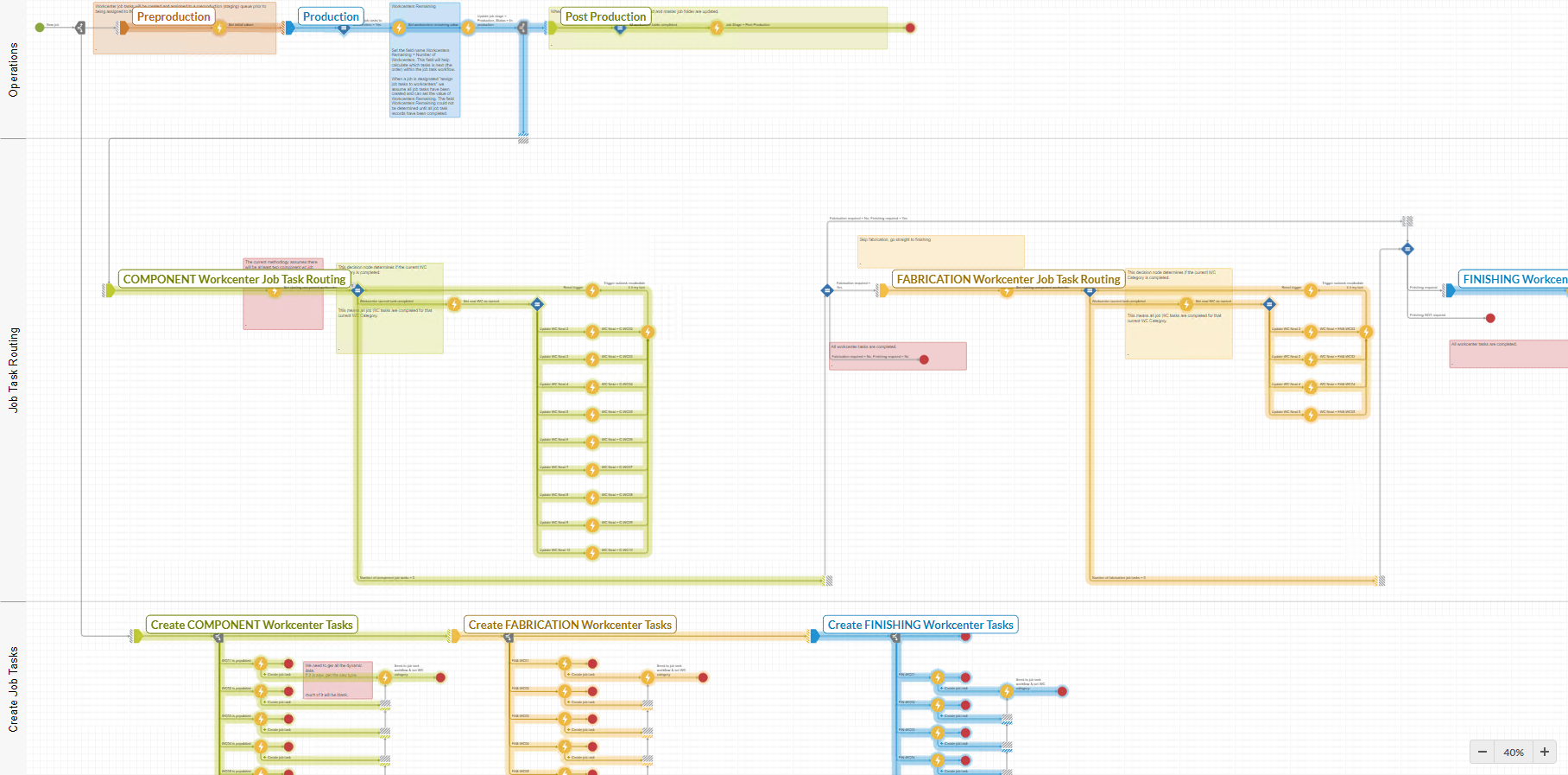

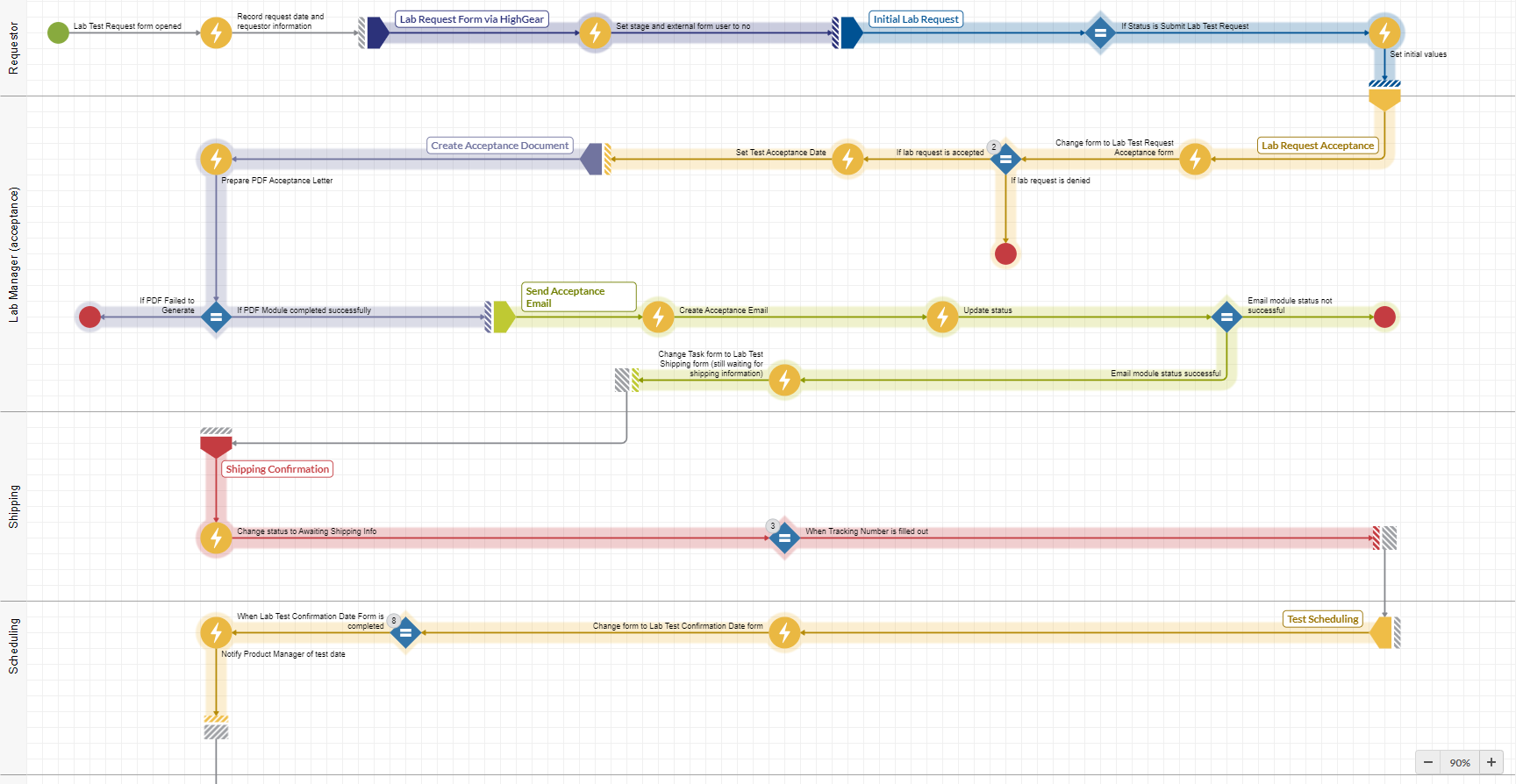

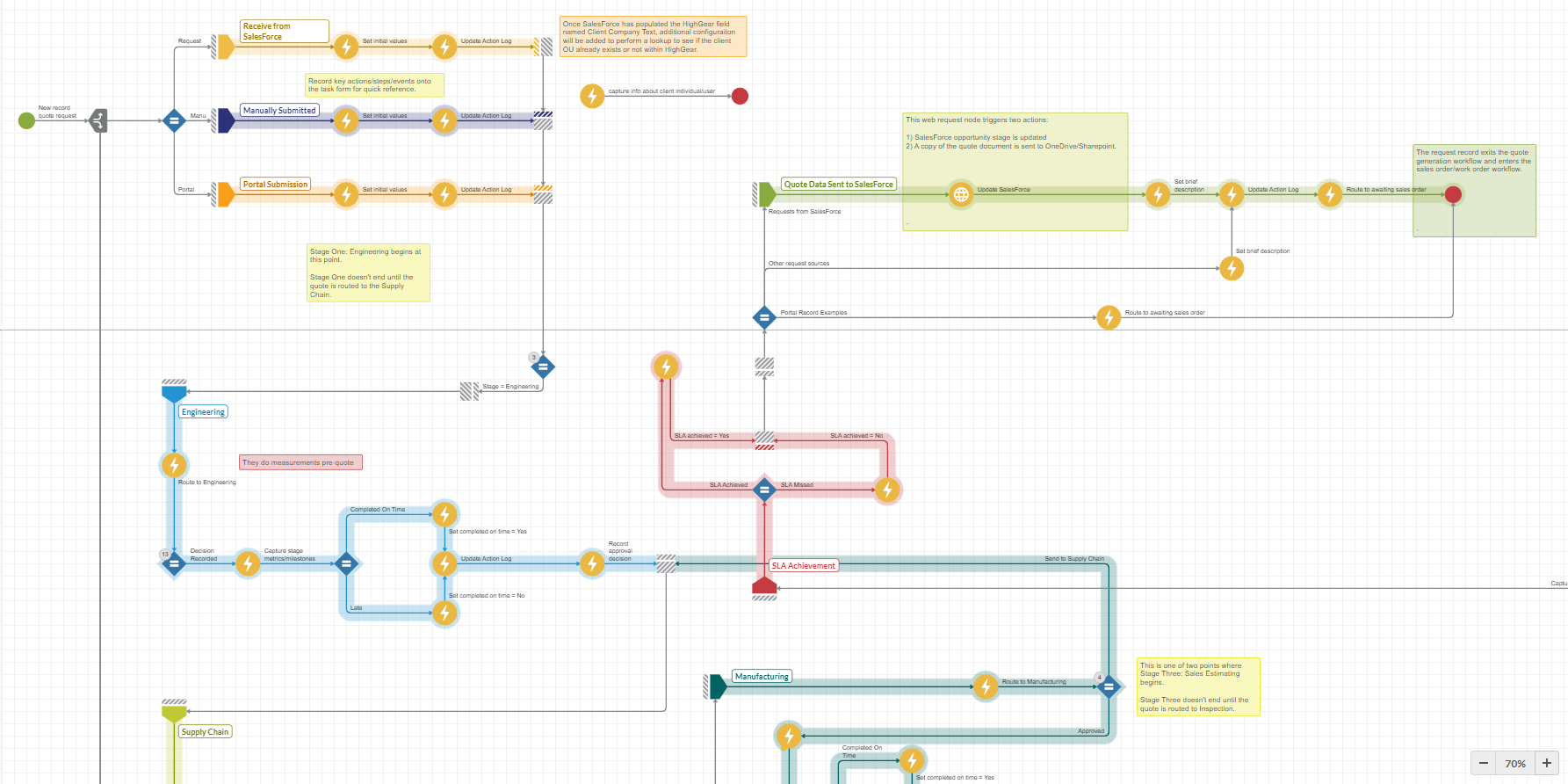

End to End Process Automation

Rapidly deploy and securely manage end to end processes.

- Manage Cross-department Work Activities, Reviews, and Approvals

- Full traceability

- Visual Drag and Drop Workflow Designer

- Configurable Dashboards

- Notifications, Alerts & Escalations

- Integrate with Enterprise Business Applications (ERP, CRM, RPA, HRIS)

Shift into HighGear and start building your workflows the easy way.

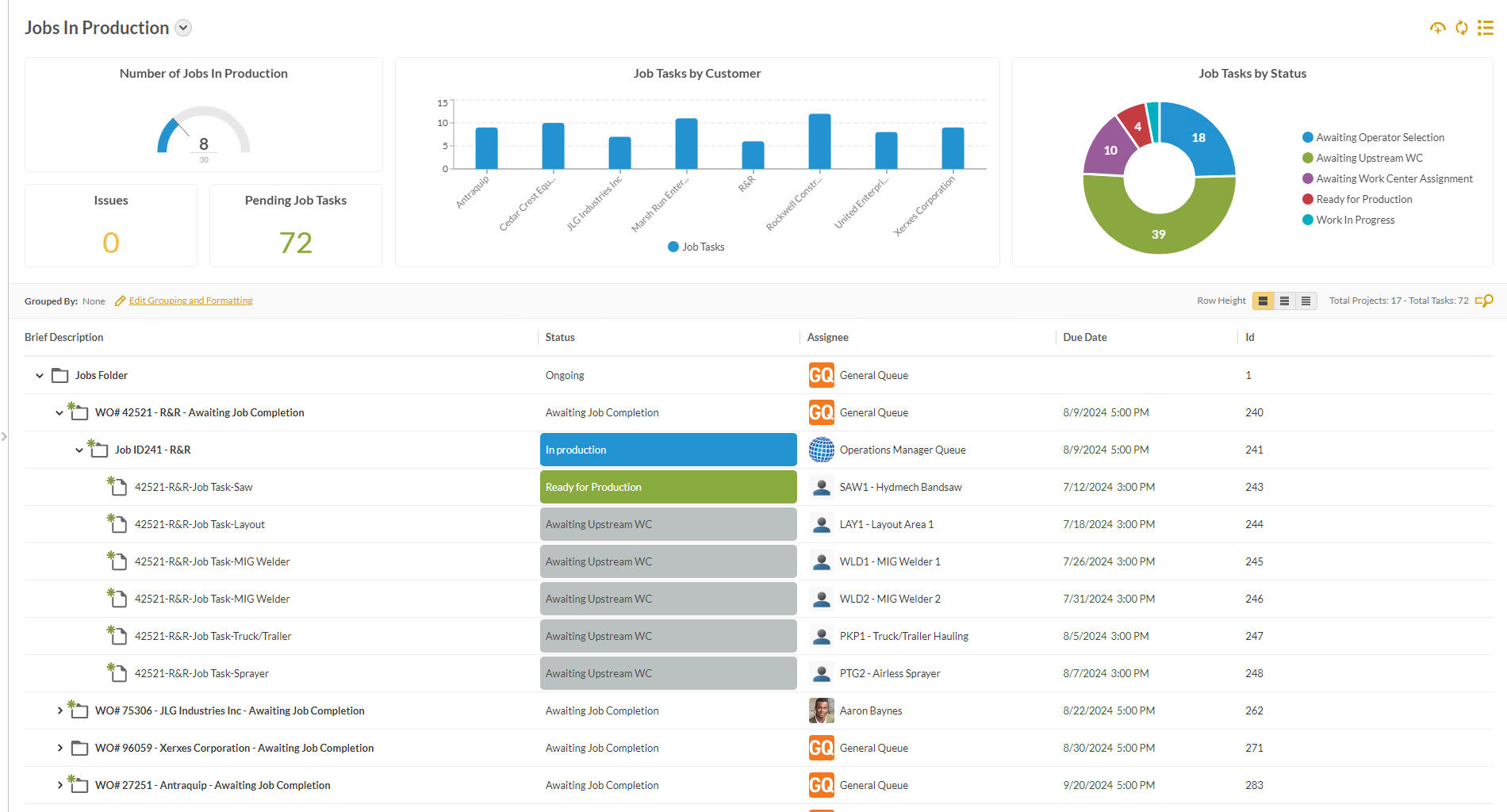

Operational Excellence

Increase efficiency across your organization.

- Easily setup and schedule jobs

- Track jobs from quote to first article, to shop floor, to customer delivery

- Enhance quality management

- Reduce manufacturing costs and cycle time

- Information is organized, easily accessible, and available when needed

Shift into HighGear and start building your workflows the easy way.

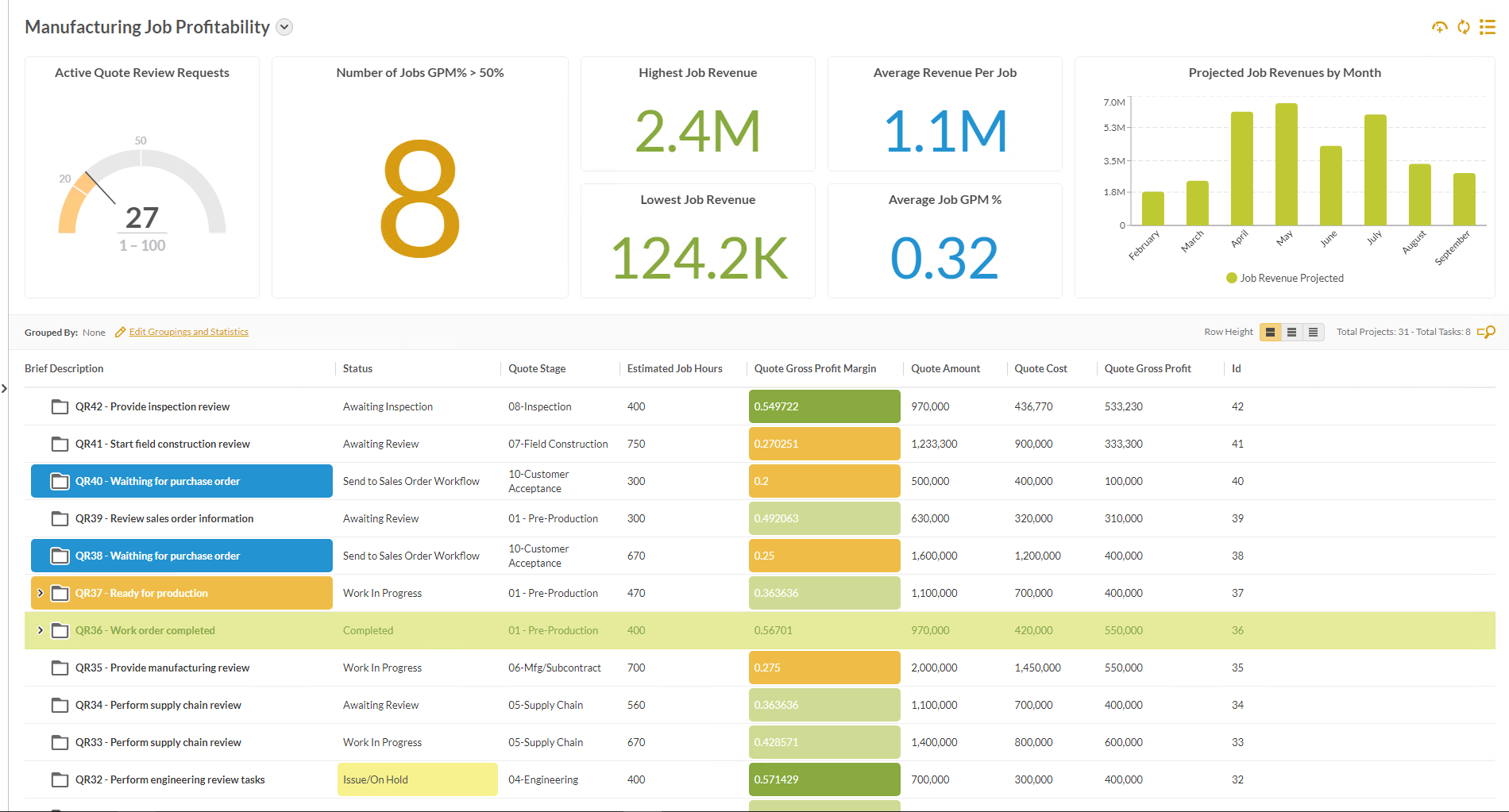

Status Tracking and Reporting

Quickly assign tasks, manage work, track progress status, and report KPIs across departments.

- Real-time project and task visibility

- Automatic report distribution

- Escalations and alerts

- Effective activity prioritization & delegation

- Work-oriented team chat & collaboration

Shift into HighGear and start building your workflows the easy way.

Audit and Compliance

HighGear provides a non-repudiated record of compliance.

- Every change from individual work history to system wide configurations is recorded

- Full audit trail

- Detailed activity logs

- Decrease audit time and expense

- Successful audit outcomes achieved

Shift into HighGear and start building your workflows the easy way.

Pioneering the Future of Manufacturing

eBook

5 Reasons Why Manufacturers Need Workflow Automation

This free guide provides five reasons why manufacturers should implement no-code workflow automation to dramatically…

Whitepaper

Blog